How to Maintain EPDM Granule Running Tracks for Durability

Every school, stadium, and sports authority wants a running track that stays safe, vibrant, and durable. However, daily use, weather exposure, and poor maintenance can quickly damage even premium surfaces.

This guide explains how proper care extends the life of EPDM granule running tracks while preserving performance and athlete safety.

You’ll learn essential cleaning methods, inspection routines, seasonal care tips, and expert advice trusted by PFS Sports worldwide.

Understanding EPDM Granule Running Tracks

What Is an EPDM Granule Track?

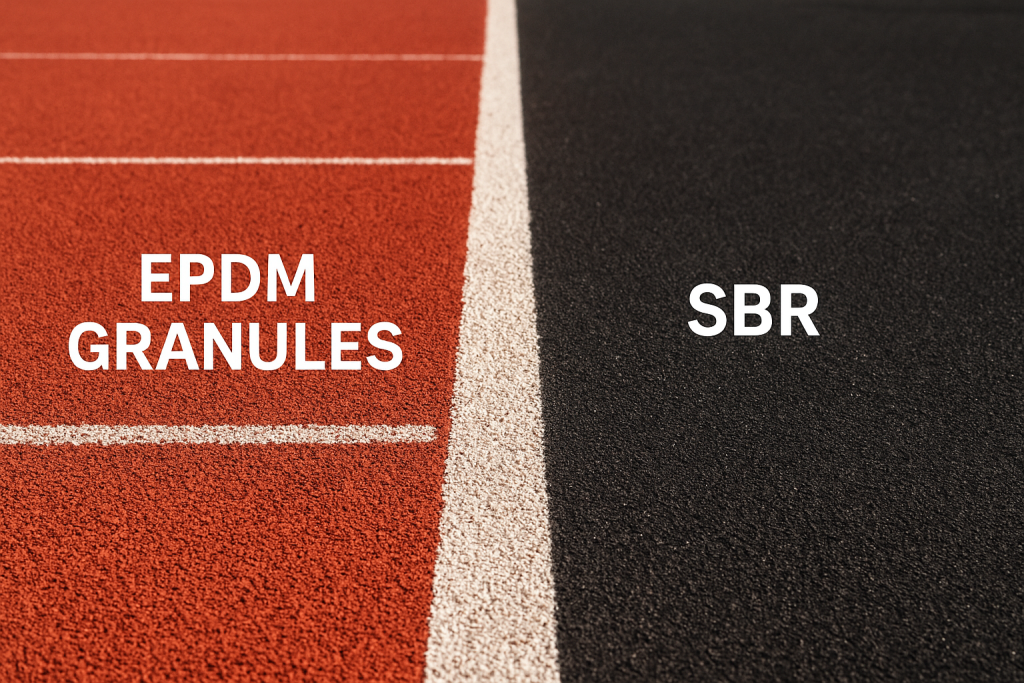

EPDM granule running tracks use synthetic rubber granules bonded with polyurethane. These surfaces deliver excellent shock absorption and weather resistance. As a result, athletes experience reduced joint stress and consistent traction. EPDM Granule systems also maintain color vibrancy for years when maintained properly.

Why Maintenance Matters

Although EPDM granule tracks are durable, neglect accelerates surface wear. Dirt buildup, standing water, and UV exposure gradually weaken bonding layers. Regular maintenance protects performance, aesthetics, and safety standards. Moreover, well-maintained tracks significantly reduce long-term repair costs.

Key Benefits of Maintaining EPDM Granule Tracks

Enhanced Athlete Safety

Routine care ensures uniform shock absorption and slip resistance. Clean EPDM granule surfaces reduce fall risks and joint strain. Therefore, athletes train confidently across seasons.

Extended Surface Lifespan

Consistent maintenance prevents premature cracking and granule loss. Schools and stadiums enjoy maximum return on investment. PFS Sports designs EPDM systems that respond best to proactive care routines.

Cost Efficiency Over Time

Preventive maintenance costs far less than resurfacing. Minor repairs addressed early save significant future expenses.

Daily and Weekly Maintenance Practices

Routine Surface Cleaning

Loose debris damages EPDM granules over time. Therefore, sweep tracks daily using soft brushes or mechanical blowers. Avoid metal tools, as they can loosen bonded granules.

Weekly Washing

Wash tracks weekly with clean water. Low-pressure washing removes dust and pollutants safely. Never use harsh chemicals, as they weaken polyurethane binders.

Monthly Inspection Checklist

Check for Granule Loss

Inspect high-traffic zones such as curves and start lines. Early detection allows quick spot repairs. EPDM Granule systems from PFS Sports are engineered for easy patching.

Assess Drainage Performance

Standing water indicates drainage issues. Address slopes and outlets immediately to prevent surface damage.

Monitor Surface Elasticity

Press test areas for elasticity consistency. Hard spots may signal binder fatigue requiring professional attention.

Seasonal Maintenance Tips

Monsoon and Rainy Season Care

Clear drainage channels before heavy rainfall. Remove organic matter frequently. Excess moisture accelerates surface deterioration if neglected.

Summer Heat Protection

High temperatures increase UV exposure. Light rinsing during peak heat helps cool surfaces and preserve color vibrancy.

Winter and Cold Weather Measures

Avoid sharp tools for ice removal. Use rubber squeegees instead. EPDM granules remain flexible in cold climates when properly maintained.

Do’s and Don’ts of EPDM Granule Maintenance

Do’s

- Use soft cleaning equipment

- Schedule professional inspections annually

- Repair small damages immediately

- Follow manufacturer guidelines

Don’ts

- Avoid harsh detergents

- Do not drag heavy equipment

- Never allow prolonged water stagnation

Professional Maintenance vs DIY Care

When DIY Works

Daily cleaning and inspections work well in-house. Staff training ensures consistent upkeep.

When to Call Professionals

Annual resurfacing checks and deep repairs require experts. PFS Sports provides professional EPDM track maintenance services globally.

How PFS Sports Ensures Long-Term Durability

Advanced EPDM Granule Quality

PFS Sports uses UV-stable EPDM granules for long-lasting elasticity and color retention.

Proven Installation Techniques

Proper installation ensures easier maintenance. PFS systems meet international athletic standards.

End-to-End Support

From design to maintenance guidance, PFS Sports supports clients throughout the track lifecycle.

Common Maintenance Mistakes to Avoid

Ignoring Small Cracks

Minor cracks quickly expand without attention. Early repairs protect underlying layers.

Overwashing the Surface

Excessive washing weakens binders. Follow recommended cleaning schedules strictly.

Maintenance Schedule at a Glance

Daily

- Debris removal

Weekly

- Water cleaning

Monthly

- Surface inspections

Annually

- Professional assessment

Sustainability Benefits of Proper Maintenance

Maintained EPDM granule tracks reduce material waste and environmental impact. Long-lasting surfaces align with eco-friendly sports infrastructure goals supported by PFS Sports.

Conclusion

Maintaining an EPDM Granule running track is essential for safety, durability, and long-term cost efficiency. With proper cleaning, inspections, and seasonal care, facilities can preserve performance for years. PFS Sports combines premium EPDM technology with expert guidance to deliver tracks that last longer and perform better.

👉 Invest in durability—partner with PFS Sports today: https://www.pfs.sport/