PU Binder Application Guide: Best Practices for Sports Surfaces

Poor surface bonding is one of the biggest reasons sports flooring fails early. Cracks, loose granules, and uneven layers frustrate facility owners and athletes alike.

The right PU Binder application can dramatically increase surface strength, safety, and lifespan.

In this guide, you’ll learn step-by-step best practices, expert techniques, and how PFS Sports ensures world-class sports surface performance through precision PU Binder application.

PU Binder Application Guide for Sports Surfaces

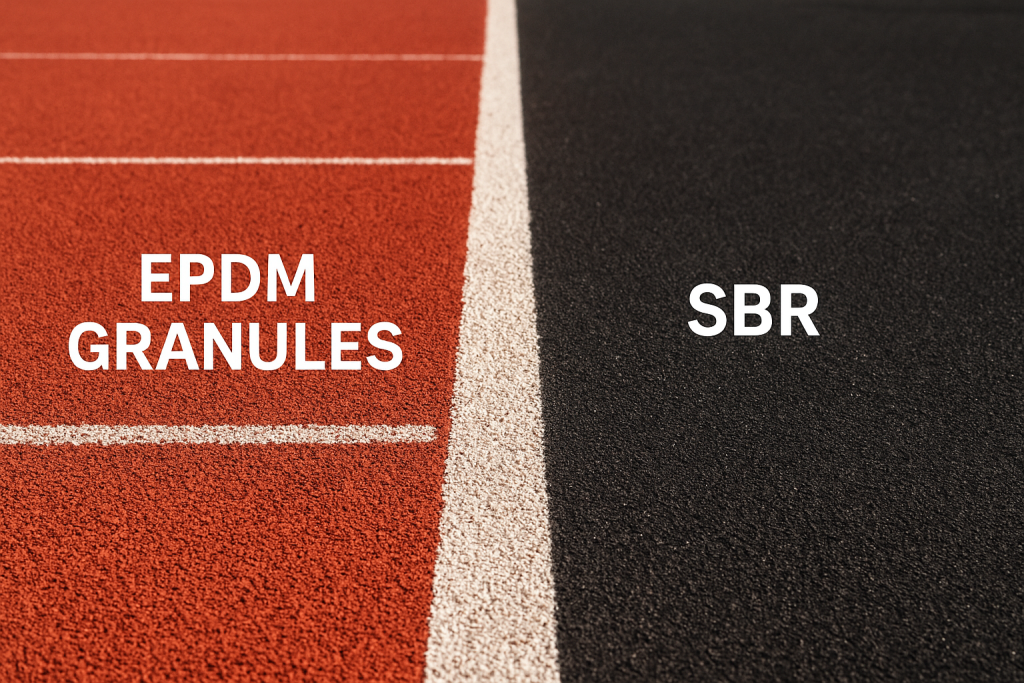

PU Binder plays a critical role in modern sports flooring systems. It acts as the glue that binds EPDM granules, rubber crumbs, and aggregates into a resilient, shock-absorbing surface. When applied correctly, PU Binder enhances durability, elasticity, and athlete safety across tracks, courts, and playgrounds.

What Is PU Binder and Why It Matters

PU Binder is a polyurethane-based adhesive designed for high-performance sports applications. It provides exceptional bonding strength while maintaining flexibility.

Unlike traditional adhesives, PU Binder withstands heavy loads, weather changes, and constant foot traffic. That’s why PFS Sports uses premium-grade PU Binder in all professional sports flooring systems.

Key Properties of PU Binder

High Elasticity

PU Binder absorbs impact efficiently, reducing stress on athletes’ joints.

Weather Resistance

It resists UV exposure, moisture, and temperature fluctuations.

Strong Adhesion

PU Binder securely locks granules together, preventing surface breakdown.

Sports Surfaces That Require PU Binder

PU Binder is essential for a wide range of sports flooring systems.

Running Tracks

EPDM granules rely on PU Binder for seamless, shock-absorbing track surfaces.

Multi-Purpose Courts

Basketball, tennis, and futsal courts benefit from flexible yet firm bonding.

Playgrounds & Fitness Areas

PU Binder improves safety by creating impact-resistant surfaces.

Preparing the Surface Before PU Binder Application

Proper preparation determines the success of PU Binder application.

First, the base must be clean and dry. Dust, oil, or moisture reduces adhesion strength. Next, surface leveling ensures uniform binder distribution. PFS Sports follows strict substrate preparation standards to guarantee flawless results.

Ideal Mixing Ratio for PU Binder

Incorrect ratios weaken surface performance.

PU Binder must be mixed precisely with granules or aggregates as per manufacturer specifications. Over-binding causes stiffness, while under-binding leads to loose surfaces. PFS Sports uses calibrated mixing systems to maintain consistency across projects.

Step-by-Step PU Binder Application Process

Step 1 – Material Inspection

Always verify binder quality, shelf life, and viscosity.

Step 2 – Controlled Mixing

Mix PU Binder evenly with EPDM granules using mechanical mixers.

Step 3 – Uniform Spreading

Apply the mixture evenly using trowels or paving machines.

Step 4 – Compaction

Light compaction removes air pockets and ensures bonding.

Optimal Weather Conditions for Application

PU Binder reacts to environmental conditions.

Ideal temperatures range between 10°C and 30°C. High humidity or rain can disrupt curing. That’s why PFS Sports schedules installations strategically for optimal results.

Curing Time and Post-Application Care

PU Binder requires adequate curing time for full performance.

Typically, surfaces cure within 24–48 hours. During this phase, foot traffic must be restricted. Proper curing ensures long-term durability and surface integrity.

Common PU Binder Application Mistakes to Avoid

Many failures occur due to avoidable mistakes.

Over-application causes brittleness. Under-application leads to surface erosion. Inconsistent mixing creates weak zones. PFS Sports eliminates these risks through trained technicians and strict quality control.

Why PFS Sports Sets the Industry Standard

PFS Sports (Polska Fabryka Sportów) is trusted globally for premium sports flooring materials.

We use high-quality PU Binder, advanced machinery, and tested application techniques. Our solutions meet international sports standards while delivering long-term value.

Sustainability and PU Binder

Modern PU Binder formulations support eco-friendly construction.

Low-VOC options reduce environmental impact without compromising performance. PFS Sports prioritizes sustainable materials for future-ready sports infrastructure.

Maintenance Tips for PU Binder-Based Surfaces

Routine cleaning extends surface life.

Avoid harsh chemicals. Use mild detergents and regular inspections. Prompt repairs prevent minor issues from escalating. Well-maintained PU Binder surfaces perform consistently for years.

Choosing the Right PU Binder Partner

Material quality alone isn’t enough.

Expert guidance, installation support, and after-sales service matter. PFS Sports provides end-to-end solutions, ensuring every project meets professional standards.

Conclusion

PU Binder is the backbone of high-performance sports surfaces. When applied correctly, it enhances durability, safety, and long-term value. From surface preparation to curing, every step matters. PFS Sports combines premium PU Binder materials with expert application practices to deliver world-class results. Whether you’re building a running track or multi-sport court, choosing the right PU Binder solution makes all the difference.

👉 Explore professional PU Binder solutions at https://www.pfs.sport and build surfaces that last.