How PFS Sport Ensures Quality in Sports Flooring Materials

Every athlete, school, and sports facility expects flooring that performs consistently. Poor sports flooring risks injuries, surface damage, and expensive repairs.

This guide explains how PFS Sports guarantees premium sports flooring quality across all materials and installations.

You’ll learn about raw material selection, testing standards, manufacturing controls, installation expertise, and long-term performance assurance from PFS Sports.

Why Quality Matters in Sports Flooring

Sports flooring directly impacts athlete safety, gameplay performance, and facility reputation. A low-quality surface wears quickly and becomes unsafe.

Therefore, PFS Sports follows strict quality benchmarks. Every flooring solution delivers durability, shock absorption, weather resistance, and visual consistency.

High-quality sports flooring reduces injuries, maintenance costs, and downtime. It also ensures compliance with international sports standards.

Understanding Sports Flooring Materials

What Defines Premium Sports Flooring?

Premium sports flooring combines:

- Structural strength

- Elastic shock absorption

- UV and weather resistance

- Consistent surface texture

PFS Sports engineers every product to balance performance and longevity.

Material Selection at PFS Sports

Certified Raw Materials Only

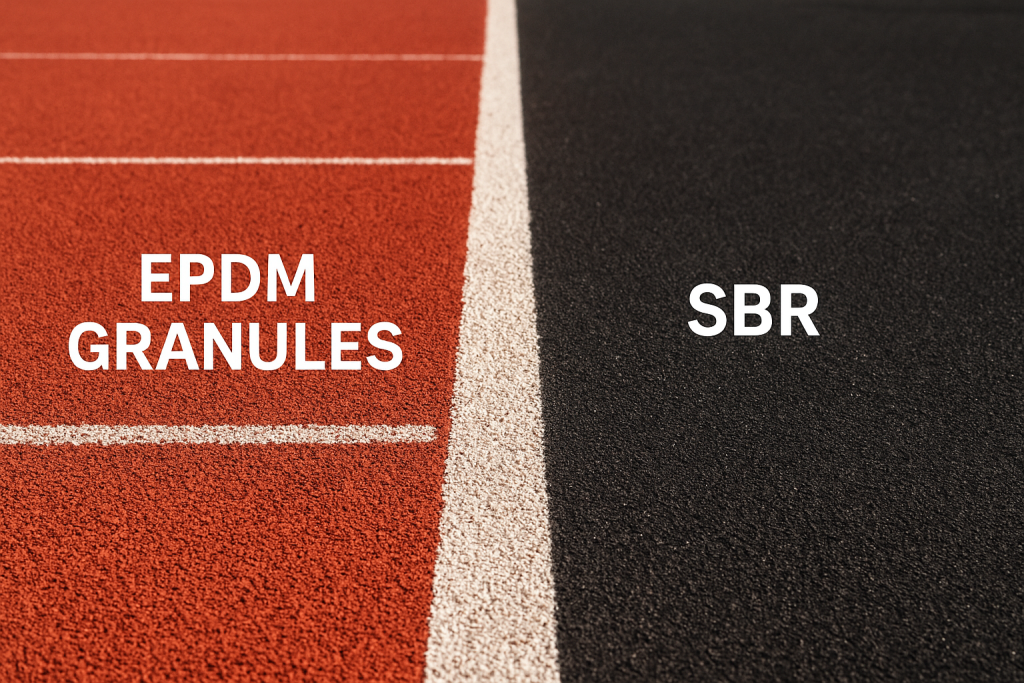

Quality begins with raw materials. PFS Sports sources certified polymers, EPDM granules, PU binders, and acrylic resins.

Each batch undergoes laboratory inspection before production begins. This prevents inconsistencies and material defects.

As a result, sports flooring surfaces remain stable across climate conditions.

Advanced Manufacturing Standards

Controlled Production Processes

PFS Sports follows precision manufacturing protocols. Automated mixing ensures uniform compound distribution.

Temperature-controlled curing strengthens surface integrity. Every layer bonds correctly, preventing peeling or cracking.

This process guarantees consistent sports flooring quality across projects.

Quality Testing at Every Stage

Pre-Production Testing

Before installation, materials are tested for:

- Tensile strength

- Abrasion resistance

- UV stability

- Elastic recovery

This ensures the sports flooring performs under real-world stress.

On-Site Performance Testing

During installation, PFS Sports performs surface checks. Flatness, thickness, and drainage are verified.

Therefore, every project meets international performance expectations.

Compliance with Global Standards

International Certifications

PFS Sports aligns with:

- World Athletics guidelines

- ITF & FIBA surface norms

- EN and DIN standards

Compliance ensures safe, professional-grade sports flooring for schools and stadiums.

Expert Installation Teams

Skilled Engineering Execution

Quality materials require expert installation. PFS Sports deploys trained technicians for every project.

They follow precise layering techniques and curing timelines. This guarantees long-term surface stability.

Thus, sports flooring remains resilient even under heavy usage.

Surface Performance Optimization

Shock Absorption & Grip

PFS Sports designs flooring to absorb impact efficiently. This reduces joint strain and injury risk.

Surface grip remains consistent in wet and dry conditions. Athletes enjoy safe, controlled movement.

This performance edge defines premium sports flooring.

Weather Resistance Engineering

All-Climate Durability

Sports facilities face extreme heat, rain, and UV exposure. PFS Sports formulates weather-resistant flooring systems.

Surfaces resist fading, cracking, and water damage. This ensures year-round usability.

Reliable sports flooring protects long-term investments.

Sustainability & Eco-Friendly Practices

Environmentally Responsible Manufacturing

PFS Sports integrates eco-friendly practices. Low-VOC materials and recyclable components reduce environmental impact.

This approach supports green infrastructure goals while maintaining performance quality.

Sustainable sports flooring benefits athletes and communities alike.

Maintenance & Lifecycle Support

Long-Term Quality Assurance

Quality doesn’t end at installation. PFS Sports provides maintenance guidance and inspection support.

Regular upkeep extends surface life and performance.

This proactive approach ensures your sports flooring delivers value for years.

Customization Without Compromising Quality

Tailored Designs & Colors

Facilities demand unique aesthetics. PFS Sports offers custom colors, markings, and layouts.

Despite customization, material integrity remains unchanged. Performance stays consistent.

Thus, creative sports flooring never sacrifices safety.

Applications of PFS Sports Flooring

Where Quality Makes the Difference

PFS Sports delivers premium sports flooring for:

- Athletics tracks

- Padel & tennis courts

- Multi-sport arenas

- School playgrounds

Each surface meets sport-specific requirements.

Why Choose PFS Sports for Sports Flooring?

Proven Expertise & Trust

With global project experience, PFS Sports stands for reliability.

Clients trust their technical knowledge, certified materials, and project execution excellence.

This commitment defines industry-leading sports flooring quality.

Future Innovations at PFS Sports

Continuous Improvement

PFS Sports invests in R&D to enhance durability and sustainability.

New material technologies improve athlete comfort and surface longevity.

Innovation keeps their sports flooring ahead of industry trends.

Conclusion

Quality sports flooring ensures safety, durability, and peak athletic performance. PFS Sports delivers excellence through certified materials, advanced manufacturing, strict testing, and expert installation. Every surface reflects precision engineering and global compliance. From schools to stadiums, PFS Sports creates reliable sports flooring that lasts.

👉 Upgrade your facility with premium sports flooring. Visit https://www.pfs.sport/ today and partner with quality you can trust.