PU Binder for Wet-Pour Rubber Surfaces: Complete Guide

Every sports surface must handle intense usage, weather changes, and athlete safety. However, many facilities struggle with surface cracking, weak bonding, or early wear.

This guide explains how PU Binder solves these problems while improving strength, flexibility, and lifespan in wet-pour rubber surfaces.

You will learn what PU Binder is, how it works, its benefits, application methods, maintenance tips, and why PFS Sports delivers industry-leading solutions.

Understanding PU Binder in Modern Sports Surfaces

PU Binder acts as the backbone of wet-pour rubber flooring systems. It binds rubber granules together to form a seamless, elastic, and durable surface. Because of its chemical stability, PU Binder ensures surfaces stay resilient under stress. As a result, sports tracks, playgrounds, and multi-use courts perform consistently for years.

PFS Sports uses premium-grade PU Binder engineered for long-term performance. This ensures reliable bonding even under extreme weather conditions.

What Is PU Binder?

PU Binder is a polyurethane-based adhesive designed to bind rubber granules into a unified surface. It remains flexible while offering exceptional tensile strength. Therefore, surfaces resist cracking and deformation over time.

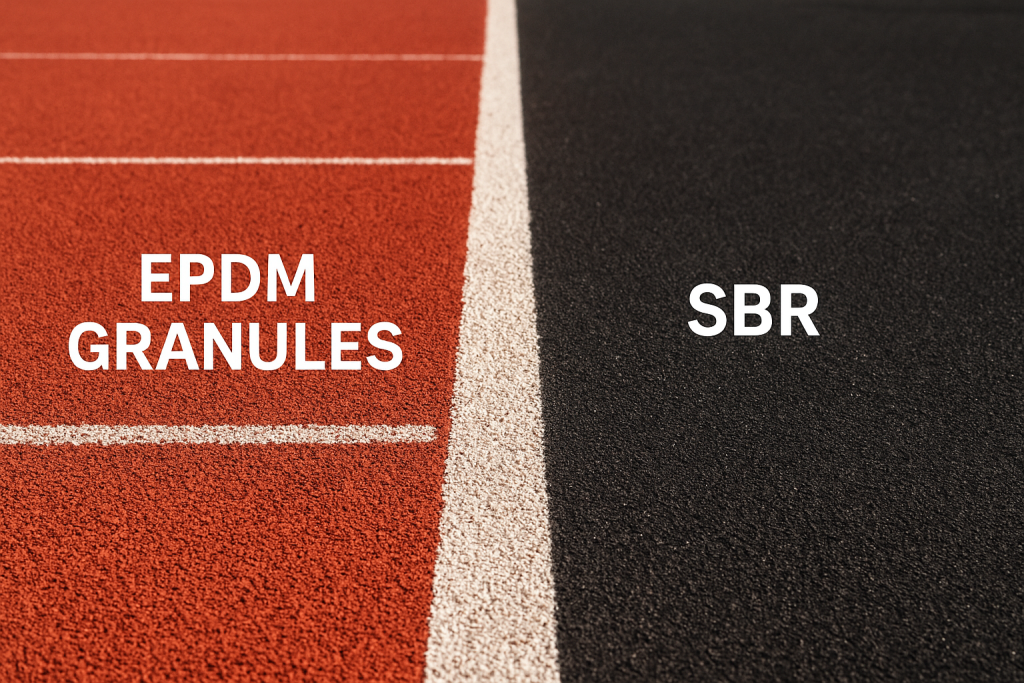

In wet-pour systems, PU Binder mixes evenly with EPDM or SBR granules. This combination creates shock-absorbing surfaces ideal for athletic and recreational use.

Why PU Binder Is Essential for Wet-Pour Rubber Surfaces

Superior Bonding Strength

PU Binder creates a strong chemical bond between granules. Consequently, surfaces maintain integrity even under heavy foot traffic.

Long-Term Durability

High-quality PU Binder prevents premature wear. Therefore, facilities reduce repair and replacement costs significantly.

Flexibility Under Pressure

Unlike rigid adhesives, PU Binder flexes naturally. This reduces surface cracking during temperature fluctuations.

Applications of PU Binder in Sports Infrastructure

PU Binder supports a wide range of sports and recreational installations.

Athletic Running Tracks

Wet-pour tracks rely on PU Binder for elasticity and traction. Athletes benefit from improved performance and reduced injury risk.

Children’s Playgrounds

PU Binder enhances impact absorption. As a result, playgrounds meet safety standards while remaining visually appealing.

Multi-Sport Courts

Basketball, volleyball, and futsal courts gain stability and longevity through PU Binder-based systems.

PU Binder Composition and Technology

PU Binder consists of advanced polyurethane polymers. These polymers react with moisture to cure effectively. Therefore, installation remains efficient in controlled conditions.

PFS Sports selects PU Binder formulations that balance curing speed, elasticity, and environmental resistance. This ensures optimal performance in diverse climates.

Key Benefits of Using PU Binder by PFS Sports

Weather Resistance

PU Binder withstands UV exposure, rain, and temperature shifts. Hence, surfaces remain functional year-round.

Enhanced Safety

The elastic nature of PU Binder improves shock absorption. This reduces joint stress and injury risks.

Eco-Conscious Formulations

Modern PU Binder options minimize volatile emissions. PFS Sports prioritizes environmentally responsible materials.

Step-by-Step Application Process of PU Binder

Surface Preparation

A clean, dry base ensures optimal bonding. Dust and moisture removal is essential before application.

Mixing PU Binder with Rubber Granules

Installers mix PU Binder evenly with EPDM or SBR granules. Proper ratios ensure consistent curing and strength.

Laying and Leveling

The mixture spreads uniformly using specialized tools. Smooth leveling ensures even thickness and performance.

Curing Time

PU Binder cures naturally within recommended timelines. Controlled conditions accelerate durability development.

Common Mistakes to Avoid During PU Binder Installation

Incorrect mixing ratios weaken bonding. Additionally, rushed curing reduces surface lifespan. Therefore, professional installation remains crucial.

PFS Sports provides expert guidance to avoid these costly mistakes.

Maintenance Tips for PU Binder Wet-Pour Surfaces

Routine cleaning preserves surface integrity. Avoid harsh chemicals, as they may degrade PU Binder over time.

Periodic inspections identify minor issues early. This proactive approach extends surface longevity significantly.

PU Binder vs Other Binding Materials

Compared to cementitious binders, PU Binder offers superior elasticity. It also outperforms epoxy binders in outdoor conditions.

Therefore, PU Binder remains the preferred choice for modern sports infrastructure.

Why Choose PFS Sports for PU Binder Solutions

PFS Sports delivers world-class sports surfacing solutions across global markets. Our PU Binder products meet international quality and safety standards.

We combine material expertise, technical support, and project consultation. This ensures flawless installations every time.

Conclusion

PU Binder plays a critical role in wet-pour rubber surfaces by delivering strength, flexibility, and long-term durability. From running tracks to playgrounds, it enhances safety and performance. By choosing premium PU Binder solutions from PFS Sports, facility owners ensure reliable, cost-effective, and high-quality installations. Whether you plan a new surface or upgrade an existing one, PU Binder remains the smart investment.

👉 Explore advanced PU Binder solutions today at https://www.pfs.sport/